ACCUMAX DOCTOR BLADE

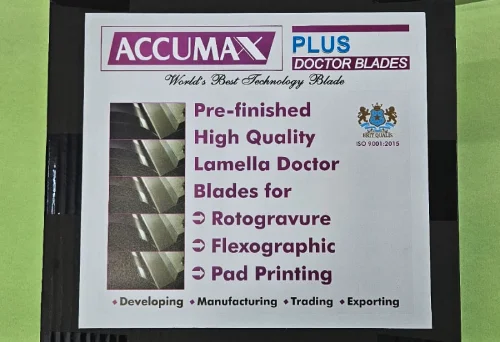

:PLUS LAMELLA DOCTOR BLADE

:PREMIUM LAMELLA DOCTOR BLADE

: SPR6 LONG LIFE DOCTOR BLADE

ACCUMAX STAINLESS STEEL DOCTOR BLADE

ACCUMAX ROUND EDGE DOCTOR BLADE

ACCUMAX POLYMER BLADES

Doctor Blade

In rotogravure printing the Accumax doctor blade removes the excess ink from the smooth non-engraved portions of the image carrier and the land areas of the cell walls. Accumax Doctor blades are also used in other printing and coating processes, such as flexo and pad printing for the same function.

Design

Given that a blade is necessary to remove the excess ink from a cylinder that is continuously running, the blade/cylinder combination is designed such that it is (chiefly) the blade that wears away, not the cylinder. The doctor blade is cheap and disposable and the gravure cylinder or flexo anilox is relatively expensive. Typical materials for the blade are steel or plastic: gravure cylinders are normally hard-chrome plated and aniloxes may be chromed or ceramic.

Important process variables in gravure coating & printing are the rotational position at which the blade wipes the cylinder; the angle that the blade makes with the tangent to the cylinder at the contact point; and the pressure applied to the blade. Fine adjustment of in-and-out position, independently on left and right, must also be possible, in order to compensate for any misalignment between blade geometry and cylinder axis. These requirements are fulfilled by a doctor blade assembly which includes a doctor blade holder.

Oscillation

In order to keep the wear pattern as even as possible, and to help prevent any particles in the angle between blade and cylinder, all except the smallest machines use oscillating doctor blades. The entire doctor blade assembly oscillates from side to side. The oscillation, flexibility of the blade, and the various possible misalignments and problems due to a lack of stiffness may result in the failure to achieve the desired angle of contact between the blade and the cylinder, or at least a failure to consistently achieve this desired angle.

Replacement

Of necessity, the doctor blade must be easy and quick to replace. On many machines, the doctor blade holder is easily removable from the machine and the replacement of a doctor blade is done by removing the blade holder from the machine; discarding the old blade; inserting the new blade; and then replacing the blade holder + new blade in the machine.

ACCUMAX DOCTOR BLADE

Pre-ground Doctor Blades for rotogravure, flexographic & Pad printing applications. To match demands for high printing speeds, the blades are manufactured in different grades of top-quality steel specially adapted to specialized printing processes and environments. The pressure exerted by the blade on the cylinder is constant avoiding uneven wear of the blade & the need for regrinding.

| ACCUMAX Doctor Blades stand for maximum accuracy that’s why whenever you order ACCUMAX BLADE you can be sure of getting: |

| + Exact straightness + Uniform structure without in homogeneities or harmful inclusions + Accurate flatness + High wear resistance + Constant contact area throughout the blade wear + Easy color matching + Increased cylinder life due to decrease in doctor blade pressure + No change in tonal values during print run + Approx. six time better life as compared to conventional blade. + Less downtime during blade change thus reducing expensive equipment downtime & wastage of ink, substrate & time. |

These blades can be used for chemically etched, electronically engraved cylinders or even for ceramic anilox rollers. We recommend a doctor blade angle of approx. 55-60 degrees. However the optimum installation angle can vary between the individual printing press, doctor blade holders & cylinder types,

| Blade angles: | |||

|

| ||

The correct installation of ACCUMAX doctor blade is:

| |||

We supply blades in continuous lengths in coils of 50 & 100 meters packed in a safe recyclable, environment-friendly dispenser box. We are a company that knows about doctor blades because we make them & complement this knowledge with an understanding of the operating environment whether this be the employment of Doctor Blades on electronically engraved or chemically etched cylinders or even if is used on flexographic printing machine.

“CROSS GRINDING TECHNOLOGY“ KEY TO PERFECTION

At “ PRINTTECH” we developed the unique “Cross Grinding Technology”. This technology allows to manufacture of lamella & bevel edges with the finest surface finishing.

With PRINTTECH’S Cross Grinding Technology, the ground edge surface is smooth & totally “marks free”.

Grinding marks (parallel or transversal) are causing faster blade wear and originate blade cracks.

The super smooth “Mirror-like” PRINTTECH’s edge eliminates such marks granting the most consistent printing quality & the longest blade life.

Conventional solutions:

The dynamic zone

Sharp edges in the dynamic zone cause the breakage of the doctor’s blade.

Grinding pattern

Accumax Doctor blades with longitudinal grinding patterns are exposed to break where the longitudinal

streaks overlap with the

crystalline lines of fracture.

Lapping

Unlapped doctor blades negatively influence the function during the start-up of printing job (waste of printing substrate).

PRINTTECH’S solutions:

The dynamic zone

The lamella parallel zone has a smooth radius to the full-thickness base material.

Grinding pattern

The fine cross-grinding pattern of PRINTTECH INDIA Doctor Blades results in the best possible surface quality of the lamella.

Lapping

ACCUMAX Doctor Blades have lapped lamella tips. With

the use of an especially fine-lapped

edge the doctor blade wipes the cylinder 100% clean from the first meters of each printing job.

Cost savings

• Longer service life

• Less waste

• Less problems

. Lower costs Cost savings

ACCUMAX POLYMER BLADES

Our Related Products

Printtech India is a leading Wholesaler and Trader of Rubber Tube, Air Chucks, Doctor Blades, Bar Coater and much more.

Contact Us